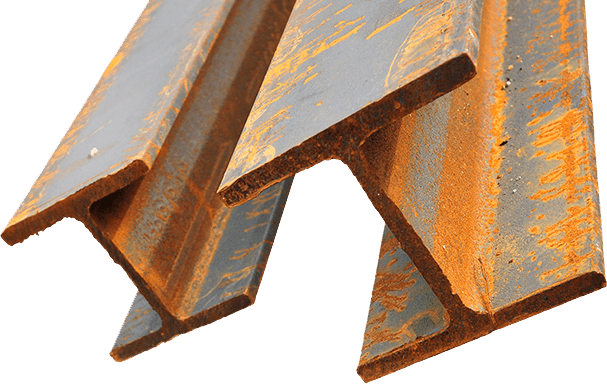

for Fabricators, stockholders, distributors

Protube Engineering offer an exceptional and unique range of machinery and technologies for efficient processing of open and closed profiles, structural steel and plate. Beam and plate processing, plasma, oxy, laser and water jet cutting in 2D and 3D, sawing and pipe profiling, straightening, bending and rolling, tailored robotic welding, weld preping, radius deburring, material handling and workflow automation are all part of our range of solutions.

Thermal Cutting

Machines

Protube

State-of-the-art drilling and sawing machines or thermal cutting and drilling machines (combined or stand-alone) with automatic feeding, measuring, marking, scribing, sorting etc. matching every conceivable demand in today’s competitive structural steel market.

Multi-function machines

drilling, counter sinking,

external counterboring, threading,

centrepointing and marking

more info@protube.com.au

Thermal Cutting

Machines

MicroStep

Protube supply a wide range of advanced CNC machines and concepts equipped with plasma, laser, oxyfuel, waterjet and 3D mill technologies. Besides machine mechanics, we develop and supply advanced control systems for machine tools and CAM software with custom modules for various applications. In the field of plasma cutting, MicroStep counts among the world’s largest and most reputable manufacturers.

The bevelled facts

Up to 50% of parts produced in the CNC cutting industry worldwide need to have bevelled edges, yet few machines are installed with bevel stations. The reason may be the additional cost of this advanced equipment, but mainly it is a low awareness by decision makers in engineering companies of the possibilities, availability and reliability of contemporary bevelling tool stations. The benefits – greater precision, along with significant savings of production time and capacities – easily outweigh the higher initial investment. Moreover, in automated preparation of bevelled edges on 3D objects such as domes, pipes, rectangular or IPE profiles, the use of specialised tool stations on gantry-based machines amounts to significant financial benefits.

Direct bevelling process

bevel is cut directly into the raw material

Additional bevelling process

add bevels to parts that have already been cut with a straight tool

Auto-calibration

of tool geometry

ACTG eliminates the necessity of mechanical adjustment of the bevel head and significantly reduces setup time of the machine from several hours to a couple of minutes.

ABP – Additional Bevelling Process– enables adding bevels to parts that have already been cut with a straight tool. ABP as a supplementary feature to DBP (Direct Bevelling Process) provides several add-ons:

- it can add bevels to parts which were cut on an external machine

- it can produce parts with bevels of greater thickness than allowed by the capacity of the machine (e.g. it can cut top-Y bevel by plasma on mild steel parts with thickness > 50 mm, or add bevels to parts with thickness of up to 300 mm using an oxyfuel rotator)

- ABP can greatly minimize waste of material and save consumables

Compensation of longitudinal displacements – an optional function which ensures absolute accuracy of the cutting machine in the longitudinal direction.

ABC – Adaptive Bevel Compensation – is an advanced feature for compensation of beam deviations. ABC enables implementation of databases of compensation angles and other values for various cutting technologies (e.g. Hypertherm’s True Bevel™ technology).

-

Some of the accessories available

-

Plasma rotator

-

Automatic calibration

of tool geometry -

Tilting tool station

-

Oxyfuel triple torch

-

Drilling tool station

-

Inkjet writer

-

MicroPunch

-

Automatic plate alignment

-

CCD camera

-

Second touchscreen

on the gantry -

ABP scanner

Automated line for

production of steel

structure parts

Automated lines of the DS type are an effective means to achieve high productivity in flanged parts production. This is achieved mainly through automation of loading input material and automated removal of finished parts, thus greatly minimizing the time required for material handling. They also help reduce the number of workers needed for the operation of the machine.

Used by some of the world’s most prestigious manufacturers Nearly 2000 MicroStep machines operate throughout the world.

-

-

-

-

-

-

-

-

-

-

-

more info@protube.com.au

Cambering &

Rotating

machines

Stierli-Bieger

Stierli-Bieger AG develops and manufactures sophisticated horizontal bending and straightening machines, turning devices and storage systems. In 1936 the first bending machine was produced and has steadily been developed since then. Today Stierli-Bieger AG is the world leader in premium horizontal bending and straightening machines. The customer base includes the metal production and processing industry, as well as machinery, ship and rail manufacturers throughout the world. All Stierli-Bieger machines are delivered with CE confirmation, assuring utmost safety and performance.

www.stierli-bieger.comStraightening and cambering machines

up to 600 tons

Horizontal and radial bending machines

complete range

Rotating and swinging without a crane

STIERLI produce the best quality ROTATOR. The rugged construction ensures long life and safety.

- Save more than 30-40% working time

- Increase your productivity

- Return on investment in a few months

- 360° turning of heavy profiles, beams and welded constructions

- Ergonomic welding and working in any position

- Autonomous and flexible - no waiting for the crane

- Bi-directional & ajustable working height

- Simple to operate

- Different sizes with different loading capacities

- Mobile system

- Earth connection integrated

- Increases operator safety

- Reduces unproductive waiting times.

- The ROTATOR can be integrated in a BEAM LINE

- Can be combined with an automatic welding robot

& mechanized

welding Machines

Protube

We specialise in CNC-controlled 3D pipe profile cutting machines and automated welding equipment. These machines are available in the RB Compact, RB Classic, RB Heavy-Duty and PB Robo series. The machines of the RB Compact, RB Classic, RB Heavy-Duty series, essentially intended for round pipes, operate with macro-controlled software. This means that the machines can be quickly programmed online, offline or via CAD/CAM modules for the profiles to be cut with the aid of already available cutting macros. The machines of the PB Robo series, designed mainly for beams, have a freely programmable software architecture that facilitates the autonomous generation of the cutting profiles offline with the use of CAD/CAM modules. Plasma and oxy-fuel are available as cutting processes.

Plasma & oxy-fuel cutting

for pipe diameters up to 4064 mm

Cutting profile examples

virtually unlimited range

Internal welding jig

for the submerged arc welding of longitudinal seams in pipes

Automated pipe shops

tailored combination of various systems (materials handling systems, machines and software) for boosting efficiency

Robots &

Systems

IGM

IGM offers complex customized solutions for automated welding and cutting processes. The product variety for individual applications in the area of robot welding technology is unique throughout the world. With over 30 years’ experience in the development of welding robots and in the planning of customer-specific welding production units, we offer an extensive range of system modules.

www.igm-group.comDeburring

Tools

Protube

Hand-held pneumatic and electric powered tools for de-burring, chamfering or applying a radius to holes, slots, edges, etc. These tools are small, easy to handle and versatile, producing an accurate and repeatable high quality cut edge. Especially useful where the edges of holes are required to comply with coating specifications (mining, shipbuilding, architectural, etc). Ideal for internal contours: holes, oblong holes, slots, cut outs (down to 8 mm Ø) on cleats, plates & profiles and are most suitable for high volume edge preparation work. Full range of consumables and spares available.

Pneumatic hand-held deburring tools

small, easy to handle & versatile

Bevel shearing machines

upper and lower bevel by flipping the machine in the rack

more info@protube.com.au

Consumables & Wear Items

Protube Engineering supplies many consumables and wear items for the metal fabrication sector. Customer satisfaction always comes first. For this reason, our products and technologies are developed and manufactured in first class companies on the basis of the highest standards for quality.

Protection

Liquid

Protube

This anti spatter weld protection liquid is bio-degradable, water soluble, solvent and silicone free, no odour, practically neutral pH, provides corrosion protection for a short period and is skin friendly.

- Significantly less rework

- Suitable for all materials

- No odours when welding

- Non-flammable

- Odourless

- Not a hazardous product

Blades

Protube

Cost optimization and conservation of resources are the success factors for efficient manufacturing processes. Combining high-tech products with outstanding service is the key to meeting the rising demands in the quality of cutting and the need for higher efficiency. Benefit from our broad personal advice. We offer excellent solutions custom-designed to meet your specific needs. Not only will you increase your productivity, but also save time and money. You can depend on partnering with ProTUBE. We will help you increase the accuracy of all your cutting activities.

Client feedback

Thank you, it has not been an easy project to say the least. I think jig-less robotic welding of structural steel has to be one of the most challenging things to automate, but also very rewarding. Protube’s continued support is very much appreciated.Project Team Leader –

I must say this gesture has been comforting and it is pleasing to see the support shown throughout this transaction. Very pleasing. I thank everyone involved.Operations Manager –