Tube making lines

Protube Engineering, together with its partners, specialise in the supply of plant, machinery, parts and consumables for the tube and profile making industry. Together we have designed and realised numerous standard lines, as well as highly specialised equipment for our broad-ranging clients. Below are some of our key partners.

Mills

OTO Fives

OTO Fives has been designing, manufacturing and installing complete units for the production of welded tubes and/or profiles for over 30 years. Considered a pioneer in the high speed line production techniques, OTO Fives experience and expertise, based on more than 700 units installed all over the world, guarantee top level equipment at competitive pricing. OTO Fives traditionally manufacture mills up to 8” but have extended their production range up to 26”.

www.otocompany.com- decoilers

- strip joiners

- strip accumulators

- welded tube mills

- cutoff units

- tube handling units

- complete lines and upgrades

more info@protube.com.au

Finishing

Tube and Profile Finishing

Our complete range of packaging solutions, including in-house cutting-edge automation technology, can process many different tube types, diameters, lengths and even customized bundles.

- complete finishing lines for tubes and profiles

- packaging machines

- chamfering/threading machines

- in-line or offline solutions

- anthropomorphous robot

more info@protube.com.au

Forming

rolls

Eurolls

Founded in 1987, Eurolls is an Italian company recognized worldwide as one of the best suppliers of tooling. Their entire process from design to heat treatment, is manufactured 100% in house. Eurolls produce tube forming rolls either in accordance with drawings or by design. A comprehensive range comprises solid and split rolls, rolls with TC inserts, floating flanges, clamps, etc. always manufactured to strict tolerances and finishes.

www.eurolls.com- special steels

- sintered materials

- various alloys

- solid carbide rolls

- For tubes made with:

- cold or hot rolled steel

- galvanized steel

- stainless steel

- incoloy

- aluminium

- titanium

- copper

Welding &

Preheating

EFD Induction

EFD Induction offers a full range of solid-state welder systems fitted with induction coils and/or contact heads. All our welders have rugged, independent full-bridge IGBT transistors. These transistors are virtually short-circuit proof, considerably boosting reliability and uptime. You also get more output thanks to our continuous electronic load matching. This secures full power output across a wide range of tube sizes (OD 3/8"-26"/10mm-600mm), ensuring maximum welding speed for each size. Moreover, you can reduce your power consumption. The efficiency from input at the rectifier to output at the coil is, at least 85-87 percent. And the use of diode rectifiers results in a high, constant power factor (0.95) at all power levels - thereby eliminating the need for costly reactive power compensation capacitors.

more info@protube.com.au

testing (NDT)

systems

Prüftechnik Fluke

Eddy current testing has become one of the most important testing methods used by industry today. It can be fully integrated in production lines, whether at low or high speeds or for cool or hot metals. It provides mill operators with immediate feedback on product integrity, allowing correction of process changes before scrap develops or serious overhauls are required. Eddy current testing is easy to install and operate providing reliable test results day after day, year after year.

- Fast, state of the art, computer based system

- All major applications requiring 1 or 2 test coils, or rotating system

- Extremely simple operation featuring touch screen monitor

- Extensive signal evaluation options

- Complete documentation of test results and statistics

- Connection to host computer or central controlling network

more info@protube.com.au

Consumables & Wear Items

Protube offers a complete range of tube making consumables and wear items, many already in stock, or can supply on short notice. The products below are just a small selection in our range.

wear items &

accessories

Eurolls

Forming rolls for the tube sector can be made of different materials such as special steels, sintered materials or from various other alloys. In case of high quality products, such as automotive or furniture applications, and whenever the production of a tube with tight tolerances is required, Eurolls offers solutions which foresee the use of combined materials, including solid carbide rolls in the most critical applications, or where rolls are subject to wear. Eurolls can produce roll tooling for tube/pipe up to 24”.

www.eurolls.comRolls for welded

tube forming

complete range

Rolls for electrical

resistance sector

forming rolls, reduction rolls, etc.

Accessories for

tube forming rolls

vices, pinch rolls, spacers

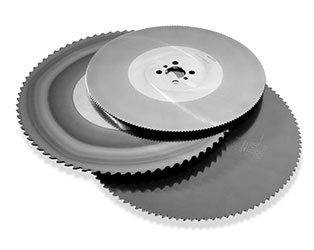

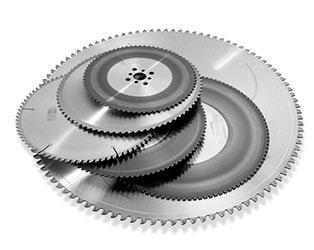

cut off

blades

SW WIL SwissCUT

Protube’s Swiss cut off blades are designed for maximum performance and cut quality. The range includes SwissCUT HR friction blades (new technology) for substantially higher number of cuts (3-4 x more compared to normal friction blades), much smaller tag and less cracking. The new SwissCUT Powerblades (45 or 65) are designed for maximum performance when cutting higher grade steels (dual grade). HSS blade features an innovative coating system for tubes and bars in the range of 450N/mm2 to 650N/mm2. The SwissCUT T (TC tipped blade) completes the range. Proven performance with all major tube manufacturers!

-

HSS power blades

-

TCT circular saw blades

-

Friction saw blades

-

Segmented saw blades

-

Segmented saw blades

-

more info@protube.com.au

Welding &

Preheating

Consumables

& Wear Items

EFD Induction

EFD are world leaders in supplying HF welders and heaters, impeders, coils, busbars etc. to the tube and pipe industry. Over the last 30 years they have worked hard to understand the principles of induction tube welding and this knowledge allows them to develop innovative products for ever increasing demands in performance.

- ferrites

- impeders

- inductor coils

- casings

- busbars

- scarfing systems

- impeder mounting systems

Complete range of outside and

inside scarfing tools and rings

full range to match individual applications

Complete range of induction coils,

ferrite and impeder assemblies

thru flow, return flow, clusters, etc.

Ferrite testers

Client feedback

Thanks for your help on this and please forward on our thanks to Eurolls for their help & diligence.Reliability & Continuous Improvement Engineer –

Fantastic news!Purchasing Officer –

Thanks very much for your help.