A solution for every need

Protube Engineering with its extensive knowledge, experience and vast array of worldwide contacts in the metal cutting, forming and processing industry, offer systems and solutions for unique tasks and applications encompassing logistic systems for storage and retrieval, loading and unloading, welding automation, specialised tooling for cold and hot shearing, to special spare parts and consumables. Our in-house engineering department takes care of all our compliance related tasks when installing and commissioning the equipment.

BandSaws

Protube

Protube offers a wide range of customised solutions. Working together with the customer, Protube can provide turnkey solutions in the sawing process and enhance the manufacturing process.

Horizontal & Vertical

bandsaws

for cutting bars, billets,

blocks, profiles, etc.

more info@protube.com.au

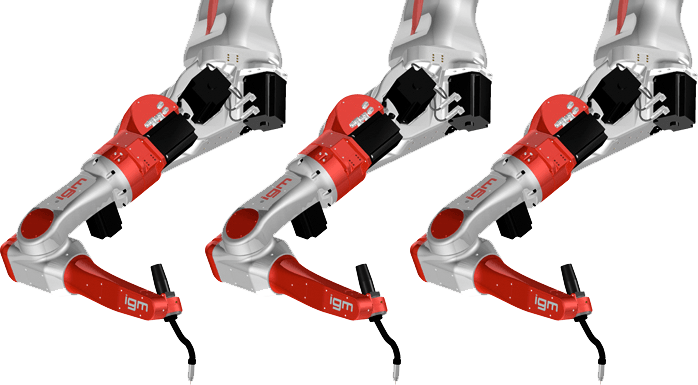

robots

IGM

There are applications supported by IGM Robotersysteme in every area of the welding and cutting industry. The IGM reputation as a specialist for large-scale projects is based on a steady stream of major contracts from the heavy engineering industry since the 1980s. Indeed, the floor track systems of up to 100m in length are designed to cater for the special requirements of this industry. Components with larger than standard dimensions such as those found in bridge construction and ship building for example, are manufactured using portal welding units capable of taking components of up to 25m in width and 8m in height. The robotic systems are utilized for manufacturing excavators, railway wagons and locomotives, for boiler making, the construction of gantry cranes, bridge construction and ship building.

www.igm-group.comStraightening

machines

Stierli-Bieger AG

Stierli-Bieger AG develops and manufactures sophisticated horizontal bending and straightening machines, turning devices and storage systems. In 1936 the first bending machine was produced and has steadily been developed since then. Today Stierli-Bieger AG is the world leader in premium horizontal bending and straightening machines. The customer base includes the metal production and processing industry, as well as machinery, ship and rail manufacturers throughout the world. All Stierli-Bieger machines are delivered with CE confirmation, assuring utmost safety and performance.

www.stierli-bieger.comBusbar bending machines

forming, bending, twisting

With or without automatic angle correction

automatic springback compensation

Flange straightening machine

automatic springback compensation

Ship frame bending machine

200, 300, 400 & 600 tonnes

Rail bending machines

available in 200, 300 & 400 tonnes

Blasting

Protube

Improved shot blasting performance by new turbine technology. The advantages of the high performance turbines include rapid assembly with no special tools required, less wear parts, and high performance shot blasting due to the high abrasive throughput. For special applications (e.g. shot peening) the high performance turbines are also designed as rotatable turbines. The top centre image below shows a rotatable turbine in a satellite turntable shot blasting machine.

& Machine Elements

TKM Austria

Böhler Miller Messer und Sägen GmbH was taken over by the German machine knife manufacturer IKS Klingelnberg GmbH with TKM being the parent company 13 years ago. The company has now decided to underline its group membership, as well as its core competences by changing to a new company name. The Böhler Miller Messer und Sägen GmbH is renamed to TKM Austria and produces industrial knives and machine elements for the paper, wood, metal, plastics, rubber and recycling industry to most stringent requirements and standards.

www.tkmgroup.comFor steel service centres

slitting, chopping, trimming

For rolling mills

shearing, trimming, chopping

For the recycling industry

granulating, shearing, chopping

- Steel service centres

- Rotary slitter knives and accessories for slitting lines

- Tooling for over-arm separators

- Cut-to-length knives (straight and chevron blades NC-ground)

- Scrap chopper knives

- KSF microplan polishing machine

- Light-weight spacers

- DYNABLOC quill assemblies for precise slitting

- CASKA – Software for Computer Assisted Tooling Set Ups

- Rolling mills

- Bar mill and structural mill knives made from steel and special alloys

- Slap shears

- Crop shears

- Cut-to-length knives

- Side trimmer blades

- Light-weight spacers

- Scrap chopper knives

- Profile shear blades

- High precision knives for laser welding lines

- Recycling industry

- Granulator knives

- Pressure lips

- Knives for guillotine shears

- Bimetal knives for agglomerators

- Scrap chopper blades

Deburring

Machines

Protube

This is a high performance belt grinding machine, where the plate is clamped electromechanically on a supporting table. The grinding unit moves on a rail system and the bevel is ground in one or more passes on the upper side of the plate. The bevel angle is stepless adjustable. A special table unit can be used for working on bigger plates.

Heating

Machines

EFD Induction

Straightening with induction heating

The thermal straightening of welded plate constructions has been a key area of EFD Induction activity since the early 1980s. Our deck and bulkhead straightening solutions are found in the ship- building industry (deck straightening), construction industry (straightening of bridges) and trains/trucks industry (production and repair of locomotives, rolling stock and Heavy Goods Vehicles). Using induction for straightening means that you get the right heat, exactly where you want it. When repairing a steel chassis on a truck, for example, there’s no need to dismount heat-sensitive components such as brakes and cables. Induction also makes life easier for staff and the environment. No gas flame to emit dangerous fumes. No flame to burn the skin. And, induction heating is easy to learn and safe to use.

EFD Induction offers brazing in various important fields such as the automotive, aviation, electrotechnical and white goods industries. It includes brazing of aluminum, brass, copper, copper alloys, iron and cast iron, steel and stainless steel. There are many reasons why using induction heating instead of gas for brazing is clearly beneficial. Induction transfers more energy per square meter than an open flame, resulting in faster heating cycles. Put simply, you produce more components per hour. The heat is also easy to check and adjust. You reduce the risk of overheating, which can lead to higher porosity and weaker joints. What’s more, you reduce the risk of cold brazing as induction generates the heat in the base material. Just as important, induction heating improves the working environment and safety. No gas needed, no open flame, no additional heating.

Machinery

Protube

These machines are used for cutting hot and cold steel.

On the basis of thermal cutting processes, Protube offers a number of machines and plants for steel mills and rolling mills to be used in continuous casting plants, in finishing lines, for scrap preparation, as well as in round deburring machines for deburring of billets. Specifically designed and highly efficient carbide cold circular saws for dry sawing, ensure almost burr-free and rectangular cuts. The range of products includes billet sawing machines, sample cutting machines, tube layer sawing machines, rail sawing and drilling machines. Cutting efficiencies and long tool lives are achieved by means of optimum vibration damping during sawing.

- Product overview

- Torch cutting machines for continuous casting plants

- Cross cutting and slitting machines

- Deburrer

- Scrap cutting plants

- Scarfing machines

- Machine cutting torches and nozzles

- Special features

- Sturdy, durable, user-friendly

and maintenance-friendly designs - Excellent quality of cuts

- Customized solutions

- Intelligent control technology

Used by some of the world’s largest steel mills Efficiency and precision qualities make these machines a wise choice.

Designed

Automation

Systems

Protube

Protube implements complete solutions for automation projects, including delivery of mechanical and electrical components, software development, assembly and commissioning.

Client feedback

Thank you for coming through this morning and providing your assistance.Engineer –

Awesome. Thank you.Roll Shop Supervisor –

That was extremely fast.

Folks, just thought I should feedback that the gear worked a treat. A great success in the end.Plant Engineer –

Thanks to all involved for going above and beyond the call of duty to make it happen.